Maintenance

Periodic maintenance, which prevents defects, often prevents a lot of misery. Production loss and breakage often cost a multiple of a simple maintenance.

We use cookies to improve your browsing experience. By continuing to use this site, you consent to the use of cookies.

CloseBRtech offers all-round service and supports you with maintenance, malfunction/diagnosis and conversion/retrofit of sheet metal working machines. You can also contact us for new or second-hand machines.

All servicesPeriodic maintenance, which prevents defects, often prevents a lot of misery. Production loss and breakage often cost a multiple of a simple maintenance.

Our 24/24h service assures you the flexibility and the necessary know-how to get your machine working again in the shortest possible time.

Often an outdated machine is still perfectly usable in terms of structure, but it is often the controls or its parts that are no longer available.

Your machine park is the beating heart of your company. It is the source of income and reflects the quality of your work to the outside world. Preventive maintenance is still too often underestimated. A periodic maintenance, which prevents defects, often prevents a lot of misery. Production loss and breakage often cost a multiple of a simple maintenance. During such maintenance it is often possible to act before breakage occurs, this prevents your company from losing a lot of money and profitability. At BRtech we are happy to support you with the continuous availability of your sheet metal working machines.

If a machine does come to a standstill due to unforeseen reasons, we can also offer help here. Our 24/24h service assures you the flexibility and necessary know-how to get your machine up and running again in the shortest possible time. After having carefully made a diagnosis, we ensure that the customer is presented with a cause-solution by means of transparent communication.

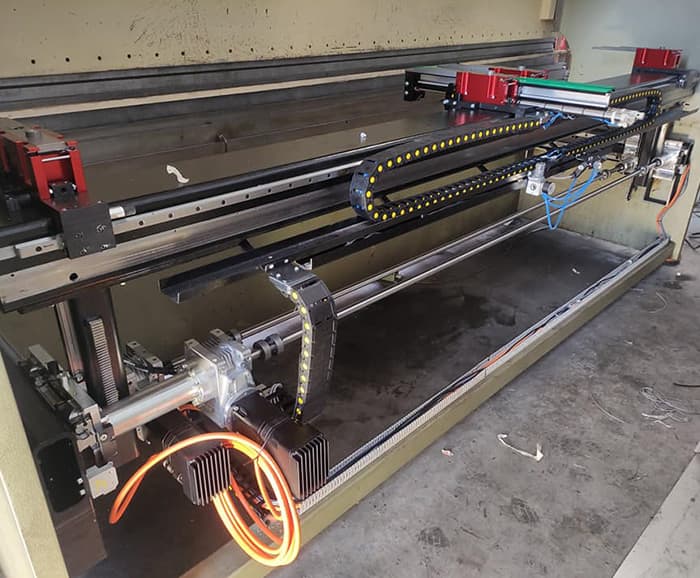

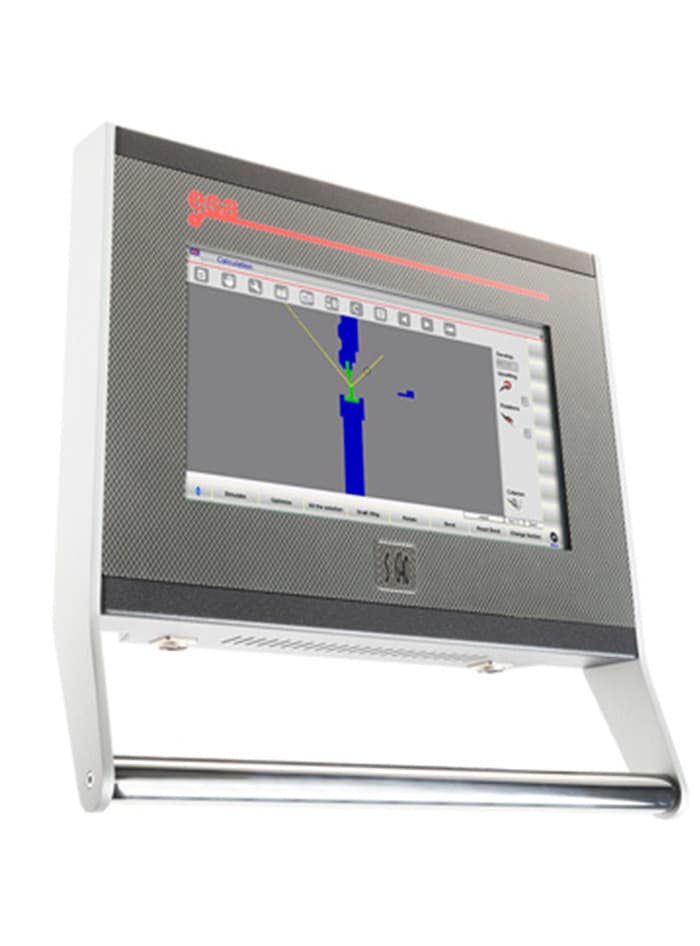

The world of sheet metal working is evolving at a very fast pace. Often an outdated machine is still perfectly usable in terms of structure, but it is often the controls or its parts that are no longer available. You can breathe new life into your machine by means of a retrofit. A thorough update or revision by a specialized technician so that you can continue working for years to come without having to dig too deep into your pocket. We therefore focus on all parts, such as the operating system, the tools and toolings, the hydraulics, robotisations and other components.

To measure straightness/flatness of machine frames (tolerance 0.01mm at 50m measuring distance) a high-tech laser was recently purchased. For example, BRtech can provide you with extra support in the recalibration of machines that can no longer meet the specified tolerances. Both national and international transfers are possible.

Are you looking for the appropriate expansion of your machine park? Then we will guide you in your search for the perfect new or used (CNC) sheet metal shears, bending machine, punching machine or laser cutting machine. We guarantee you the best price-quality ratio due to our close cooperation with major machine manufacturers (we are not brand bound). We will work with you to find the perfect match.

BRtech is not brand specific and guarantees you the best price-quality ratio. We will look for the most suitable machine from a recognized machine builder together with you.

A brief overview of various realizations and projects at our satisfied customers.

Time for a first introductory meeting or a cup of coffee! Fill in the form below - response guaranteed within 48 hours - or +32 (0)492 44 20 56!

Passchijnstraat 21

8400 Oostende (BE)